Manufacturing and testing

Manufacturing of the Urbos 100 Green Line trains is expected to begin in 2025, with the first vehicles arriving in Calgary in late 2027. Delivery of the 28 vehicles on order will be staggered over one to two years.

About the train manufacturer

After a competitive procurement process, Construcciones y Auxiliar de Ferrocarriles (CAF), a Spanish train manufacturer, was awarded the contract to supply Green Line with 28 low floor Light Rail Vehicles (LRVs). The contract also includes the tools and support for operating and maintaining this new fleet and an option to purchase additional vehicles to support the long-term vision for the Green Line.

Manufacturing process

- Train assembly takes place in the CAF production plant in Zaragoza, Spain.

- Trains are manufactured in a production line, similar to cars. However, unlike cars, there is little automation (robots) involved in the process.

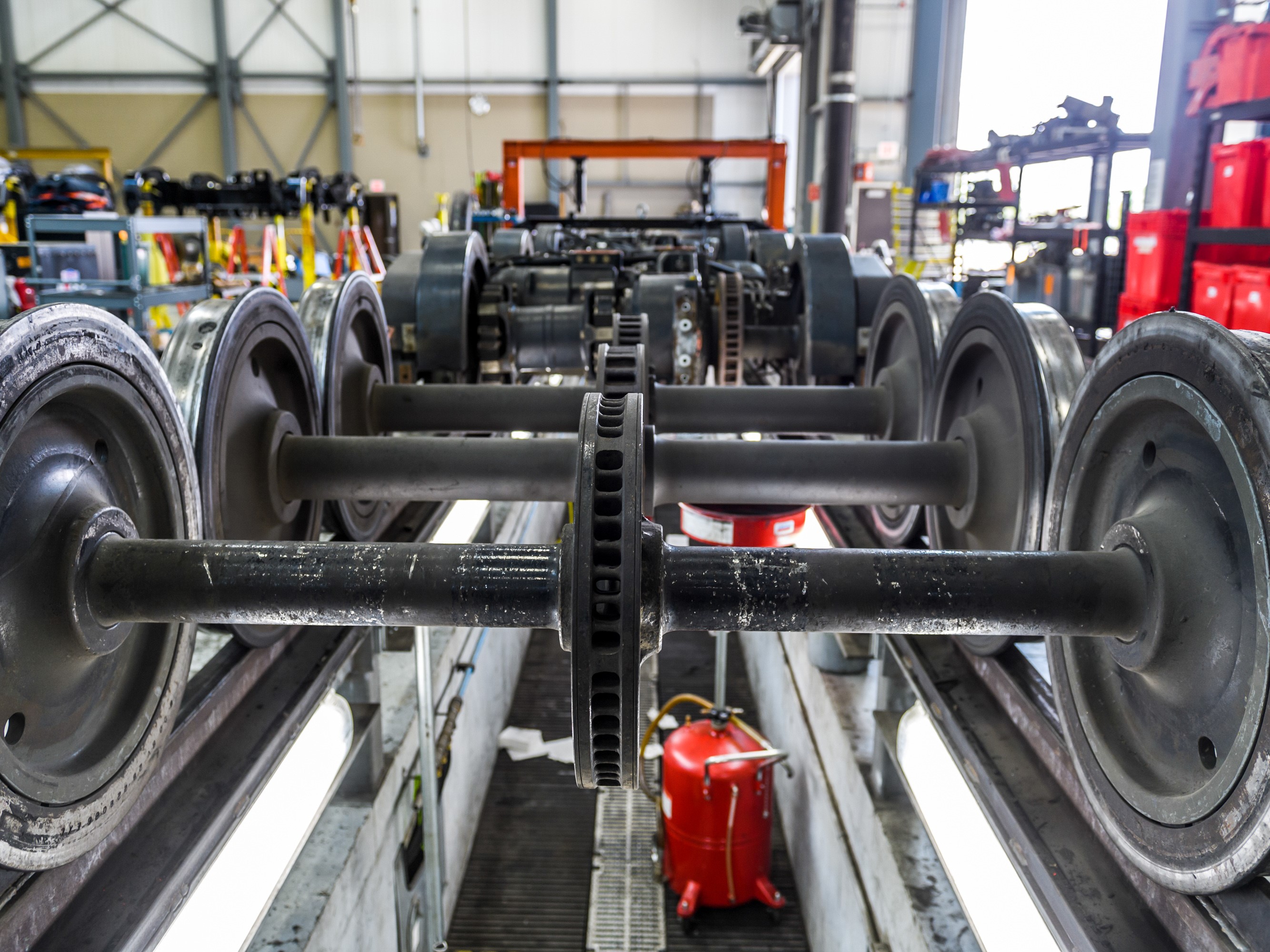

- Some components are built by CAF and their subsidiaries including the wheels, wheel sets and bogies (a chassis under a train car that holds the wheels, axles and suspension system).

- Most components are procured from sub-suppliers, then installed on the trains.

Testing

- There are multiple stages of testing (component level, system level and train level) to ensure the train will perform as designed.

- The individual train components (such as traction motors, batteries and pantographs) will be tested and validated by the sub suppliers.

- Once CAF and Green Line verify and approve the test results, the components are delivered to CAF and assembly can begin.

- Once all components are installed, tests will be undertaken to ensure all systems work together and the train functions as one unit.

- When the trains arrive in Calgary, functionality will be re-verified and they will be tested for acceleration, braking, going through tunnels and pulling up to station platforms. Radio systems and technology will also be tested and verified.

Cold weather testing

Climate chamber testing is a tool we’re using to ensure the new trains can perform in Calgary’s winter conditions. This is a stress test for LRVs, which closely emulates real climate conditions. The first manufactured LRV will go inside an indoor climate chamber where humidity, temperature and other conditions can be adjusted. The temperature will be lowered to -40 degrees Celsius, to test:

- Insulation of the vehicle body.

- Accumulation of ice and snow in the door areas.

- Functionality of window wipers, windscreen heaters and doors.

- The braking system in extreme cold, snow and more.

Delivery of trains

- 28 trains will arrive in Calgary as finished products.

- Trains will be delivered to the Maintenance and Storage Facility via ship and rail.

- Each vehicle is 42m long, making it too large to ship in one piece. Prior to delivery the vehicles will be disconnected into three parts, which will be re-assembled in Calgary.