Tunnel and underground stations

Tunnel along the West LRT CTrain line.

The information on this page reflects the previous Phase 1 alignment, which included an underground tunnel and stations in the downtown. On Oct. 10, 2024, The City and The Province announced a revised alignment is being developed for the downtown that will be either street-level or elevated.

Green Line will have two underground stations Downtown/Beltline area. These include:

Connecting these stations will be tunnels that reach depths of around 30 metres below the surface. To safely build these tunnels, two separate approaches will be undertaken: cut and cover and tunnel boring.

Cut and cover

Cut and cover is one of the oldest methods of tunnelling construction and involves digging a large trench, constructing a tunnel and then backfilling material around and over the tunnel. Once complete, the surface can be returned to its original state.

For the Green Line, this method is being used from the Eau Claire Station to 7 Avenue S.W. Station.

Support of excavation

To safely support the excavation to the required depth for the cut and cover portion of the tunnel, secant pile walls will be used as the support of excavation (SOE) method. A secant pile wall consists of overlapping columns of concrete. In our case, they are around 1 to 1.2 metres in diameter and every other pile is planned to be reinforced with steel. The columns of concrete are supported with internal bracing, consisting of large steel beams that run parallel to the walls and additional large diameter pipe braced across the excavation.

After the piles are installed, excavation and installation of the bracing begins. Once the excavation reaches the bottom, concrete will be poured to form the floor of the tunnel. As the concrete walls of the tunnel are installed the internal bracing is removed in sections as the tunnel walls continue upwards. Once the tunnel roof is completed, the remaining area above the tunnel is backfilled to the surface, and the road surface reinstated.

Tunnel boring

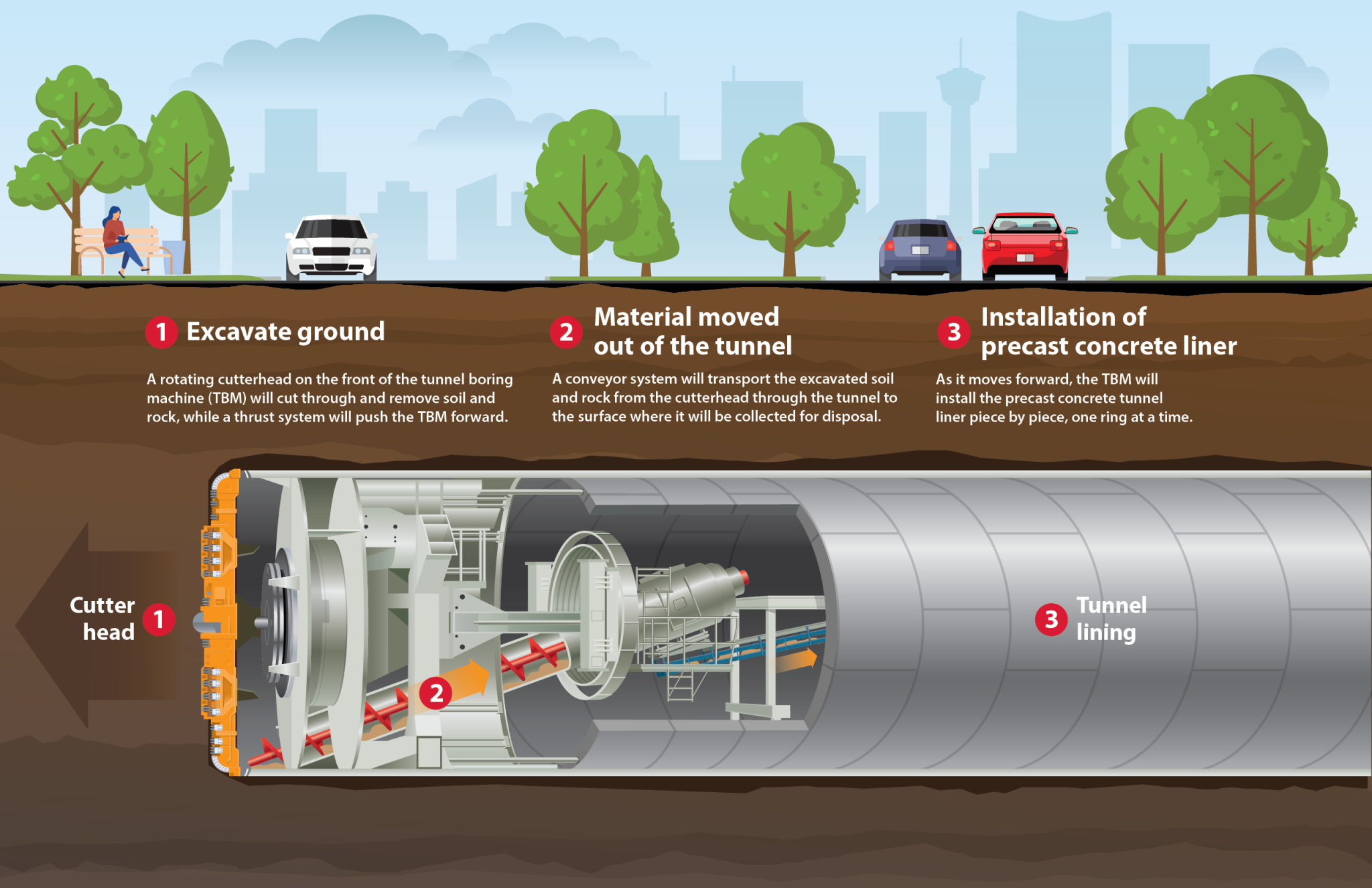

The other method that will be used to construct tunnels for the Green Line is called tunnel boring, which uses a large machine (sometimes as long as a football field) to excavate the ground without disrupting the area at the surface.

The tunnel boring machine (TBM) has a rotating cutter head at the front and a system of conveyors that remove material out the back as it digs forward. It also has a segment erector, which installs the precast concrete tunnel liner segments to form the tunnel walls as the TBM moves forward. To fill any gaps and to help them keep their shape, the TBM injects cement grout behind the liner panels.

Tunnel boring process:

- Excavate ground: A rotating cutterhead on the front of the TBM will cut through and remove soil and rock, while a thrust system will push the TBM forward.

- Material moved out of the tunnel: A conveyor system will transport the excavated soil and rock from the cutterhead through the tunnel to the surface where it will be collected for disposal.

- Installation of precast concrete liner: As it moves forward, the TBM will install the precast concrete tunnel liner segments, piece by piece, one ring at a time.

Instrumentation and monitoring

For both methods of tunnelling, detailed inspections and monitoring of groundwater levels and other underground conditions will be completed before and during the work.

Monitoring begins long before the start of tunnel construction and includes installation and monitoring of many instruments to record various aspects of the work. Some of these methods include:

- Instruments attached to structural components of buildings to measure any movement.

- Surface settlement plates to measure ground surface movement.

- Inclinometers to measure any tilting of the ground.

- Piezometers to measure ground water levels.

- Extensometers to measure the movement of utilities, the secant pile walls and the ground above the tunnel.